KB ID 0001744

Garden Pub

During lockdown in 2020 I decided that seeing as I could not go to the pub, it would be a better idea to have one of my own. I’m not a builder, but being an ex Royal Engineer I’ve got enough know how to turn my hands to most things. (Disclaimer: If you’re going to do you own electrics, get it checked by an electrician!)

Laminate and Skirting (update 19th Apr 2021

How Do I Get Internet to My Pub? (update 26th Apr 2021)

Mounting a TV Bracket (update 08 Jun 2021)

Bar Construction ((update 28 Jul 2021)

What to Buy?

Well you are faced with two choices, fabricate you own, or buy a ‘pre-built’ flat packed building (probably sold as a ‘summer house’ or ‘garden room’). I had a budget for the building of about 2-2.5k and did a lot of looking online and eventually settled on a 16’x10′ Summer house from ‘Nordic Timber Buildings’ the base building was about 1.6k but by the time I’d added a 4′ canopy and upgraded the roof felt it was just shy of 2k. The problem was that (in Jun/Jul of 2020) I could not get one delivered and built before NOVEMBER!

Prep Work (Footing)

I knew I needed something to stand it on, either a concrete pad (ideally) or I looked at plastic bases you filled with stones, or using slabs etc. I’ve done plenty of concreting in the past so that was the route I was looking at, but getting ready mixed concrete to my back garden would have been a pain. Luckily my neighbour was having a path put in his back garden, and after a quick discussion, it was arranged that he would put me down a 16’x10′ concrete pad for 1k. Now I could have done it cheaper, but 1) he’s got all the gear 2) Knows the contacts 3) Will do it much quicker than me 4) That would take me probably about 3-4 weekends to sort out myself. 5) Another lump of concrete needed removing, and it saved me hiring a breaker. Finally he agreed to do another 6’x4′ pad on the other side of the garden to put my new garden shed on, for no extra charge (sold!)

So all I needed to do was clear all the trees and branches out of the way.

The base is sat on plate compacted material that looks a lot like Dolomite (but isn’t) and it compresses rock hard (I was told it’s made from reclaimed stone and concrete).

The guy picked up the concrete as a ‘semi-wet’ mix on his flatbed, then he (and another) wheelbarrowed it to the formwork, they did it in two ‘pours’ as you can see in the photo above.

Wait

As I said above I now had to wait until November 30th 2020. The firm were great (Nordic Timber Buildings). On the day they turned up it was tipping down with rain and their route from truck to concrete pad, (down the side of my house and round other outbuildings was ‘challenging’ but credit to them they were outside my house at about 08:00 and finished by lunchtime).

Verdict: As I’m writing this I’m a few months down the line, so I’ve got a few more ‘opinions’. On the whole I’m satisfied, the company were great, communication was spot on, the assemblers were great, and it does exactly as it says on the tin.

Minor Gripes:

- Whatever they used to cut the exterior cladding at their factory was probably not as sharp as it should have been, (the edging particularly round the windows is a bit ‘ragged’. I can sort this out in time with a Stanley knife or a chisel so I can let that go.

- The door hinges are terrible! One practically had no galvanisation on it at all and by January was brown with rust. I’m planing to replace the doors (long term), so that’s not the end of the world.

- The two front doors are not terribly well fitted to be honest, I’ve got them screwed shut presently (there’s a door on the side). In the long term I’ll replace them, but they are hard to secure (i.e fit a decent hasp and staple, or some bolts).

- There are a couple of ‘Knot Holes’ I’d have liked to have seen filled, but for what I paid, I can go to B&Q and get some wood filler.

Sorting Out The Interior

Well the building was soaking to start with, it was probably stored outdoors at the factory, and had been transported in the rain, I ran the dehumidifier in there for a few days to try and get it dried out a little.

Forums / Facebook Groups and ‘Experts’

I’ve never had to insulate a wooden building before, so I joined a few groups read a few posts and asked some questions. What I learned was that unfortunately the world is full of ‘Experts’ and if you don’t do things exactly the same way they’ve done them you’re a negligent idiot, (or its all going to go wrong).

I’m not an expert (not even close) I just sponged in as much information as I could, and made a decision on what I was going to do. Then got cracking.

Moisture Barrier

Briefly, a moisture barrier is a membrane, (usually a tight woven plastic fabric) that is used to ‘wrap’ buildings. You will also see it ‘in modern buildings’ under roof tiles. It’s designed to allow water vapour to pass though it outwards and stop water coming inwards. (If you’ve ever worn GoreTex clothing you get the idea).

Q. Did you wrap the outside of your building?

A. No? I get asked this a lot. If you build a timber framed building then you wrap the ‘frame’ in a membrane, and then you clad the outside of that. For me to do the same I’d have to disassemble the entire building remove all the upright batons from the external cladding, cover the cladding in membrane and rebuild the building again? I’m not going to do that, because that’s a monumental waste of time and effort?

So I covered the ‘inside’ of my building with membrane, completely like so;

Q.What did you use?

A. Protect TF200 2.7m x 100m Roll (approx £165)

Q. How did you fix it to the walls?

A. It’s stapled, if you can get galvanised or stainless staples use those (I didn’t, I used cheap steel ones – yes they will probably rust, but they will be buried in the wall cavity and the PIR (Insulation) will keep it in place anyway).

Q. Why is it blue?

A. I’ve not got a clue, I wanted it in 2.7m widths so I didn’t have to cut it so much, and the blue was the first one I saw.

Q: Did you leave and Vents/Gaps?

A: Yes across the top of each section it’s vented to the outside to allow air flow and potentially get rid of any condensation from inside the walls after I’ve finished.

Garden Pub: Insulation

Depending on your budget, you have probably three choices, Rockwool (like the stuff that’s in your loft), PIR (Polyisocyanurate) boards, or a combination of foil/bubblewrap. I like the idea of Rockwool because it also deadens sound, and I intend to have at least one electric guitar in here. But in the end I went for PIR.

It comes with many brand names Celotex, KingSpan etc. But they are all essentially the same. It’s a layer of foil then some foam, then another layer of foil. It comes in different thicknesses I chose 50mm.

Q: Why did you choose 50mm PIR?

A: My wall batons are 62x38mm. If I put 50mm PIR in that leaves me a 12mm cavity between the PIR and the inside of the interior walls.

Q: How much was it?

A: £280 for the PIR, then you need some foil tape (I recommend you get this from Screwfix and buy the 100mm stuff it’s miles better!)

It comes in 2.4×1.2m sheets (or 6×4 in old money) The best price I found was insulation4less but BEWARE they sting you with a delivery charge. So order it all at once, and make sure you get the quantity right. Note: Later on I’ll be doing the floor so I made the mistake of ordering twice!

Installation

Put your Stanley knife away! the best way to cut this stuff is with a good old fashioned hand saw, get a decent straight edge, and always cut it 2mm bigger than you actually need it. If you can, cut it outside! The dust is terrible, it’s not harmful, but it gets in your throat, so do like I didn’t, and wear a mask!

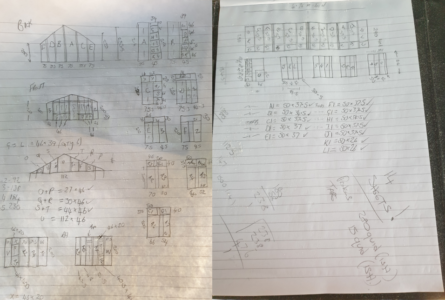

Q: How do I know how much I need?

A: I measured each piece I needed in the building, then sat and drew a page of rectangles (PIR boards) and worked out how to use the LEAST amount of boards.

Q: How do you stop it falling out of the roof and walls?

A: The more you work with it, the better you will be at cutting it correctly, by the time you finish, everything will be a snug friction fit, so that wont be a problem it will just stay there. But if you cut a little too short, get some cheap plastic headed push pins from the stationary shop they will hold it there until you need to tape it later.

Vapour Barrier

Why? If you are in a warm outbuilding and it’s cold outside, then water vapour in the air is going to form in there and you will get condensation usually on the coldest surface, (the inside face of your outside wall/cladding.) To stop that happening you need a barrier (preferably on a well ventilated air void) to protect from a build up of moisture in the walls.

You can either put up a stand alone vapour membrane (basically a decent sheet of polythene, though there are specific building membranes you can use). Or if you’ve used PIR (like I did) you can ‘Tape’ all the joints with moisture proof tape. Which is the same tape that you use to join pieces of PIR.

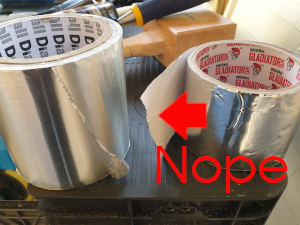

Q: What Tape?

A: Try not to get the tape thats got a backing you need to peel off, if you have nails like mine it’s a pain in the backside. I used 100mmx75m Diall insulation board tape from Screwfix it’s about £6 a roll. Get plenty! I used 4 rolls on the walls and roof, and I will need more when I do the floor.

Here you can see the roof fully taped (excuse the wires).

Walls & Lining

My original plan was to use plasterboard, because it’s reasonably cheap, and I know a good plasterer. In the end I decided to clad it it with softwood tongue and groove. This is more expensive and takes a LOT longer, but I think it will look nicer. You can of course line yours with plywood or OSB (Oriented Strand Board) old farts like me will call that chip board, but it’s a great deal stronger than chip board and is designed for use in construction, if you choose to use OSB then use OSB3 as it’s more moisture resistant.

Plasterboard Warning: I’ve seen many posts by people, who get upset when people advise to use plasterboard, because it’s porous and can get wet and degrade, there are moisture resistant (and foil backed versions). Ive not got the experience so I can comment.

I’m using 7.6mm cladding so it’s quite thin. Best advice I can give you is every few layers make sure you are level, and if you have to clad around a door or window and then ‘meet’ above it put in a vertical joint, because unless you laser level in each run they wont meet up at the same point! Unless your a master carpenter, or at least a better chippy than I am (which is not difficult 🙂

Below: I’ve finished cladding the walls. I will also clad the roof, Im just waiting on the light fittings.

Q: How did you fix the cladding?

A: Headless nails, you can normally hide the nails in the tongue and groove, but as I was using 7.5mm cladding it was a bit too thin, so its nailed directly onto the batons.

Garden Pub – Underfloor Insulation & Vapour Barrier

This time I’m using 25mm PIR and then I’ll cover with OSB, and finally lay laminate.

In fact just covering the floor in vapour permeable membrane has raised the temperature 2-3 degrees in there, and I can see how much the wind catches it!

Q: Why 25mm PIR?

A: Because the same timber I used in the batons (62x38mm) is also used in the floor but sideways on, so I can use 25mm PIR and still have a 13mm void.

Q: Why so many sockets.

A: See Below

Here’s the first section insulated and taped, BE AWARE OSB boards are 2.44 x 1.22m (because they are still 8’x4′) So don’t start screwing batons down until you’ve put them in the correct place. Your insulation boards will be 2.4 x 1.22m.

This time I cut them outside to stop choking on dust!

The following shows each section of the floor construction, and one section of the OSB in place.

Now with the OSB down, floors ready for laminate to be laid.

Q: What did it cost to insulate the floor?

A: OSB Qty 5 12mm 8×4 sheets was £150.00, the 25mm PIR Qty 5 sheets was £138.30, the 62 x 38mm timber was (approx) £55.00

Why So Many Sockets?

No I’m not planning on planning a Ganja farm. Apart from being a bar in the garden, I also intend to to be working out here, (as I work from home). And I’ll be out here with my electric guitars.

Thats still a LARGE amount! Well yes it is, but because I’ve never done this before, I decided to find out other peoples thoughts…

Now in my home, theres a constant, every single plug socket in the house has a 5 way extension plugged into it, and some more than one. What I don’t want out there is a sea of extension sockets.

As you can see from the construction, once cladded adding additional sockets (internally) will be a ball ache. BUT the next build phase is to deck outside, If I want to put external power in, it’s simple as peas to drill out the back of an existing socket.

So for every socket I ‘think’ I need I’ve put a double socket in.

Under the Consumer unit: Theres two doubles, one for EOP ethernet feed, the other in case I need a Power Injector for the Meraki AP26 Wireless point I’ll be fitting in the roof. That leave me capacity to fit a Gigabit switch, and have a spare socket in the consumer unit cupboard

Behind the Bar: Theres three doubles: Two for Beer Fridges, two for Perfect Draft beer dispensers, One for an Ice Machine, One for an Air Fryer (Shit I’ve already ran out).

That leaves me: 21 Double sockets, that’s loads right?

TV, Amazon FireTV box (Firestick don’t cut it for me), Sound Bar, PS4, Juke Box, 1060p Projector, Line 6 Guitar Amp, Vox ToneLab Guitar Pedal, My MacBook Pro docking station, my HP Elitebook Docking Station, External Monitor, MFD, Chargers for my work and personal phones.

That’s more than half of them gone already? And that’s before my daughters, visitors and visitors kids want to plug all their devices in, and jump on the wireless. Also, let’s not forget this this in my garden, it’s going to be easier to plug lawn mowers, strimmers, and hedge trimmers in here as well, (without unplugging stuff)

So no, I think I’m pretty much spot on, I’ve applied the Seven P’s

Prior, Preparation, and Planning , Prevents Piss Poor Performance.

Laminate and Skirting

Well theres no shortage of articles on how to lay laminate flooring, the best tips I can offer are;

- Mark the underside of the laminate for cutting

- Cut the laminate upside down if using a Mitre/Cut off saw

Annoyingly I was ONE BOX SHORT!

The following weekend – (and an extra box purchased), I finished off the floor and added new skirting, (and edging across the doors.)

Q. How long did it take

A. To be honest If I’d had all the gear, I could have finished it in a day.

Q. What did it cost?

A. £220.00 for the laminate, £30.00 for the underlay, and £45.00 for the skirting.

Q. How did you fix the skirting?

A. Evo Grip Rapid Adhesive (check this fits in your mastic gun! I had to trim the tube down).

How Do You Get Internet Into Your Pub?

I know above I said (I’m no expert) well on this subject (networking) I am an expert. I’m a qualified network engineer with many years experience. This must be one of the ‘most asked’ questions in groups and forums. These days everyone wants at least to be able to stream sports/films, or let the kids get on Facebook. Which needs a decent reliable fast Ethernet connection.

REMEMBER: If someone says ‘Do it like this‘ it usually means ‘I did it like that’, and to the average man in the street, if it works, it was successful right? Well that same average man will be kicking off when the FA cup final is buffering, Zoom calls don’t work properly, Spotify randomly stops playing music, and it’s generally slow and buggy. Below is each method of connecting your external building to you houses internet connection, and the actual results and connection speeds that I got testing each method.

To get an internet signal to your bar you essentially have two choices, Wired or Wireless. Wired is the most simple so let’s have a look at that first. You may not be using any of them but on the ‘Router/Modem/Access Point’ that your ISP provided for you there will be at least one network socket on the back of it. Sometimes (not always) they are coloured yellow.

You can plug in a standard Ethernet cable into one of these sockets and, (usually unless you’ve changed any router settings) plug the other end into a Computer/Laptop and get straight onto the Internet. So you can plug an ethernet cable in there and (providing the cable in long enough, run the cable into your bar/summer house and plug something onto the other end of it. Your best bet would be a wireless access point, then you can setup a new wireless network for all your pub/summer house related internet things!

I’m using all the Routers Ethernet Sockets already? Buy a cheap four or eight port Gigabit switch from eBay this will give you more ports.

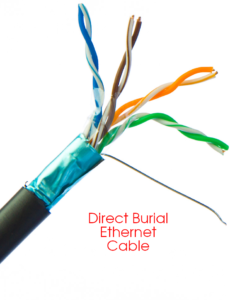

Do you need special cable? To be honest normal cat6 cable probably works for most people, however it can degrade in the cold and get brittle, if you are going to bury it, then buy ‘Direct Burial’ ethernet cable instead.

What about shielded cable? Typically it’s only for stopping RF interference between network cables, the shielding does not ‘physically‘ protect the wires, (it’s just tin foil). Though you can get armoured ethernet cable that will also suffice for outdoors and burial use.

Remember: When buying cable get it pre-terminated (plug on both ends, or a socket on one end). Otherwise you will need to terminate the cable yourself, or fit an ethernet socket in the bar.

I want Internet But I Don’t Want to Run a Cable

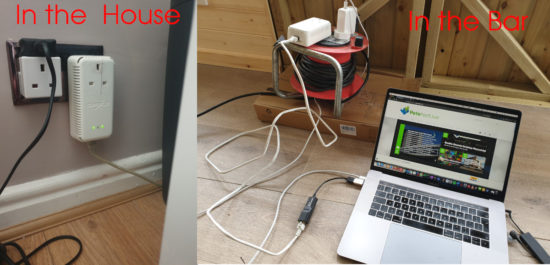

Then you have to either go Wireless, or use Ethernet over Power (EoP) sometimes referred to as ‘Powerline’. This is where you use the existing electrical wiring circuit in your house to extend your ethernet network. Assuming you have electrical power in your Bar/Summer house, then you plug one unit in, in the house and connect it to your router, then you plug the other unit in in your bar, and it gives you an ethernet socket where you want it.

It’s on a different circuit will it still work? Maybe! Sorry that’s a terrible answer, but the answer is NOT NO. Firstly dont buy cheap Powerline adaptors, you need to be spending between 60 and 150 (Pounds sterling) for a pair. I’ve got a pair of Devolo devices and I can get an ethernet signal like so

ISP Router <-> Ethernet Cable <-> Devolo Adaptor <-> Socket (in the House) <->Fusebox (in the garage) <-> Armoured Cable <-> Fusebox (in the shed) <-> Socket (In the Shed) <-> 130m Extension cable <-> Devolo Adaptor (in the bar).

What I will say, is depending on the distance you will suffer from attenuation (loss of signal strength) e.g. I get 6Mbps on the end of mine and I get 200Mbps at the router. So it’s good for Facebook and email etc, but playing Xbox or streaming video might not be as good.

Disclaimer: If you are simply on a spurred electrical connection to the house your results will be MUCH MUCH better. But compare the figures above with the wireless ones below and you will see why I chose wireless.

Connect My Bar Wirelessly to the Internet

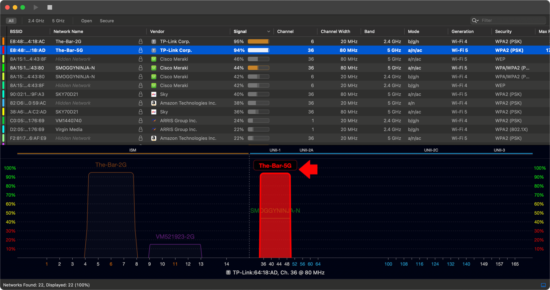

This is my preference. Before you start, the wireless you have in you house is ‘probably‘ crap, if you use the equipment that your ISP provided to you then normally that’s the case. If you want decent wireless get a decent wireless access point (MAKE SURE it supports 5Ghz). I use a Cisco Meraki MR26 My bar is 15-20m from my house and I can get 40-55% of the wireless signal from it, (download some free Wi-Fi software and take a look at your signal strength (Wi-Fi Explorer Lite I’m using below).

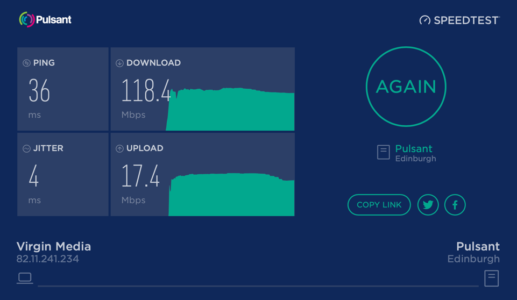

Above you can see my wireless network is about 42% What does that equate to? Well that means it performs like this;

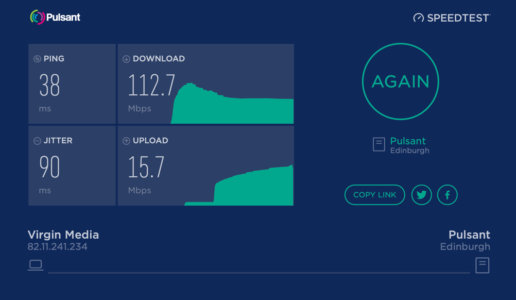

Thats more than enough for video/audio/web traffic. But those pictures are taken from my laptop (a MacBook Pro) which has a great wireless chipset in it, other things like Amazon Firesticks and visitors phones might not be so lucky. So I’m going to take that signal and ‘rebroadcast‘ it in the bar. To do that I will get a device that will join my house wireless network, then create a ‘new’ wireless network in the bar. I use a TP-Link RE650 (about 50 quid from eBay) to do this. Look at the difference in the ‘local‘ wireless strength in the bar now;

OK the internet connection speed wont be any quicker, but the antenna on the rebroadcaster will be better than ‘most’ devices I’m going to use in here. Using the new wireless network, here’s the connection speed.

Now if I want to put any wireless cameras in here for security, or smart lighting that I can control from my phone for example I don’t have to worry, as the signal in here is now great.

Garden Pub: TV Mounting

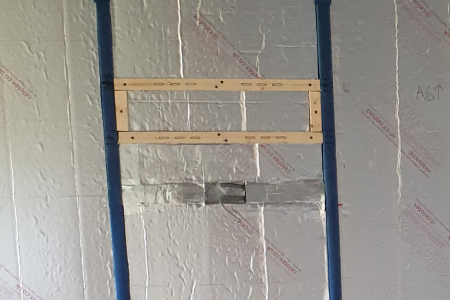

Obviously attaching an ‘heavy and expensive’ item to what is essentially a ‘shed wall’ requires some thought and planning. Most TV brackets are designed so you can screw them into a solid wall, or into the ‘batons’ in a stud wall (i.e. a timber frame with plasterboard on it*). But on a pre-fabricated building you may find (like I did) that the upright ‘studs’ are too far apart for that. So what I did, was to create a ‘Box’ within the wall that was the correct size for my TV Bracket. Then I anchored that box to the uprights and put some steel brackets inside of it to give it some strength. (It’s also screwed to the outside wall (cladding)). Below you can see it on the end wall;

*Note: To me save getting emails, you can fit a TV bracket directly onto plasterboard, IF you use the correct fixings! (Anyway I digress….)

Note: It is square! (This photo is zoomed in from an angle!)

The six markings you can see on the timber ‘marry up’ to the holes in the mounting bracket. After I’d foil taped all the, exposed studs (the blue bits!) I cladded over the top.

Q: How did you get the holes in the cladding to match up to the markings on this frame?

A: I got some flat headed nails (the ones from the electrical cable clips,) and knocked them into the centre of the markings, (and left them sitting about 10mm proud). Then when I put the cladding over the top, I simply gave it a tap with a mallet and the nail heads left an indent in the back of the cladding that I could then simply drill though the centre of.

Like so;

Testing Before Breaking Things

The last thing I wanted to do was split the timber inside the wall, or do something stupid. So I got some timber that was the same size as I’d used and used some tape on the drill bit, to make sure I didn’t drill to shallow (and risk splitting the timber) or too deep and risk putting a spyhole in for the neighbours!)

Then (to allow for mistakes and things not being as lined up as I expected), I drilled a hole deliberately ‘off-centre’, and tested putting in the anchor screws, to make sure they gripped well, that the hole was the correct diameter, and the timber would not split. (Don’t forget to use a piece of cladding also to get the correct depth).

Then it was just a case of screwing the bracket on.

Level Note: As you can see (above) the bracket is in level, the cladding itself is (slightly out), So when my TV is on there, it may ‘bother me’. But that remains to be seen!.

Q: What TV Bracket did you use?

A: It was from Amazon (I had a voucher). It was just over £30.00, it’s made by Perlgear.

Q: Why did you drill 6 holes, and just use 4?

A: To be honest I wasn’t sure how ‘robust’ it was going to be with just the anchor screws supplied. This way if I’d have been unhappy I could drill all the way through, put a metal plate outside and then use some bolts and washers to add some more rigidity. (In the end I was satisfied, so I didn’t need to do that). Plus, if it ever gets a little ‘loose’ I’ve still go that option.

Roof / Ceiling

Work had pretty much ground to a halt for a few weeks. I needed to finish the internal cladding, and just had the ceiling to do. But I was waiting for the lights to go up first. I’m exceptionally lucky, that my friend Andy is an electrician, and he was doing the lights, fusebox, and putting in the the armoured cable. The ceiling itself as you can see (above) had a moisture permeable membrane, and the 50mm PIR, that has been fully taped.

One thing I learned from cladding the walls is, MAKE SURE there’s some timber at BOTH ends of the cladding that you can secure the cladding to, or at least so it does not ‘flap around‘. If you zoom in on the picture above, you can see I’ve put in some 12mm x 400mm batons for this reason. To keep things neat, I cladded in from the ‘Outside’ to the ‘Inside’. Also for neatness I had to put in some 10mm x 15mm beading along the side of ‘some’ of the lights (another reason you should work in from the outside, you can keep all this stuff ‘symmetrical’.

Finished! That’s all the internal cladding installed. Im really pleased with the lights. They are RGB LED lights and you can control their colour form a phone app.

Garden Pub: Bar Construction

As you will have seen in a few of the pictures (above) I’ve got a Mitre/Cross Cut saw so my plan was to make the frames (carcasses) from the same cheap 38×63 mm timber I’ve used in the rest of the build, then ‘clad’ the outside with the same 7.5mm tongue and groove I’ve got on the walls and roof. This was (version2) of my original plan..

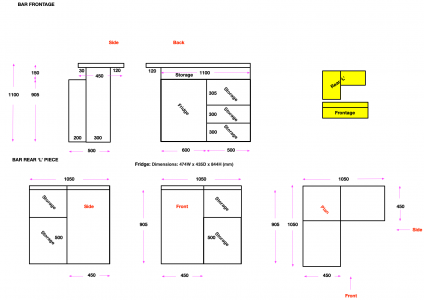

Home Bar Plans

Q: How did you arrive at those measurements?

A: Things like the height of the bar etc. I got from here and here, the length and width were dictated by the space available, and the width of the bar top.

Note: I changed the fridge location, from the front of the bar to the side, (it just fitted better there).

So first job was to make the carcasses;

Bar Top

I wanted ‘Something Decent’ for my bar top, but I know nothing about timber, so I rang a local timber merchant and asked, they suggested I used Marranti (I’d never heard of it to be honest). If I was willing to go for something thicker than the 25mm I was asking about, (in this case 32mm.) then I could get it cheaper as they had some in stock that they were struggling to get rid of. (130 quid for 25mm or 90 quid for 32mm it was a no brainer).

Remember: If you want a timber merchant to do this for you ask them to ‘Dress‘ the timber (put it though a planer, and dress it down to the size you require). They will cut it to length for you, then you will simply need to sand it.

The timber came in 225mm (dressed) widths, so two lengths together would give me the 450mm I needed for the top of the bar.

Problem: You might be able to see from the picture, (above) the ‘planks’ didn’t sit level, they were slightly warped, which meant I had ridges in the middle of the bar (not good) I fixed this, by using some skirting board I had left over, by fixing it underneath, I simply used screws to ‘pull’ both pieces flush, like so;

It worked so well, I did it across all the bar top joins.

Finishing

The sides (cladding) and the bar top I oiled with the same Danish Oil that I’d used on the walls, but I decided I would varnish the bar tops to give them a bit more protection.

Keep Up With Progress?

I hope, this has been of some help, the bar has now been named “The Sappers Rest”. You can keep up with progress, and ask me any questions on the pubs official Facebook page The Sappers Rest. Please stop by, and give the site a like and a follow, and see how it’s getting on.

Pete Long Sep 2021

Related Articles, References, Credits, or External Links

NA

09/04/2021

Come on mate…more updates and pics..plus what will you pulling into pints?

12/04/2021

🙂 Updates to follow…..

19/05/2021

Hi, please can we have some more info about the ventilation?

19/05/2021

Each roof panel is ‘Open at the back of the building’ and theres a void between the PIR that lets air circulate from there. Each wall panel is ventilated at the top, allowing free air movement all the way round.